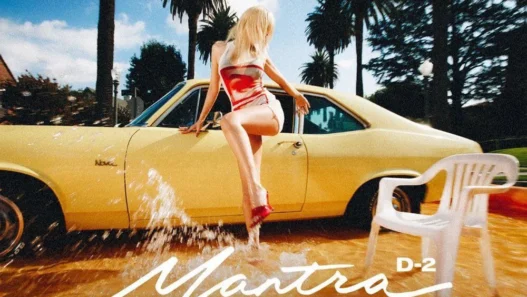

Lisa CEO Olmakta Zorlanıyor mu? BLACKPINK Üyesi, Yüksek Maliyetlerle Mücadelesini Anlattı!

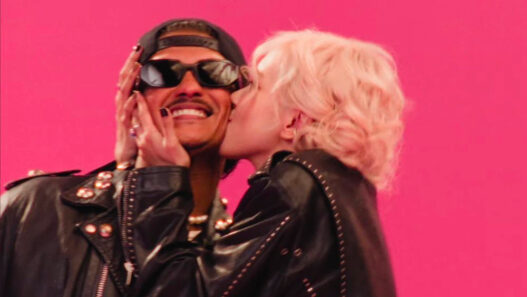

BLACKPINK’ten Lisa, geçtiğimiz günlerde konuk olduğu bir YouTube programında yeni müzik şirketi LLOUD’un CEO’su olarak karşılaştığı zorlukları anlattı. 📅 28 Şubat’ta BIGBANG üyesi Daesung’un…